The executive summary below is a preview of the revised edition of Manufacturing 4.0: A Policymaker’s Guide, to be published later in 2025.

The manufacturing landscape is undergoing a fundamental transformation. New and emerging technologies are disrupting traditional production systems and creating new global value chains. This phenomenon, referred to as Manufacturing 4.0, is reshaping how goods are designed, produced, and distributed. For policymakers across the Commonwealth, particularly in least developed countries (LDCs) and small island developing states (SIDS), this presents both an opportunity and an imperative: to modernise industrial capabilities, enhance competitiveness and ensure inclusive and sustainable growth.

The Commonwealth Connectivity Agenda developed this guide to support governments in navigating this shift. It provides a practical framework for understanding the impact of Manufacturing 4.0 and designing policy environments that unlock its benefits while mitigating its risks.

The opportunity

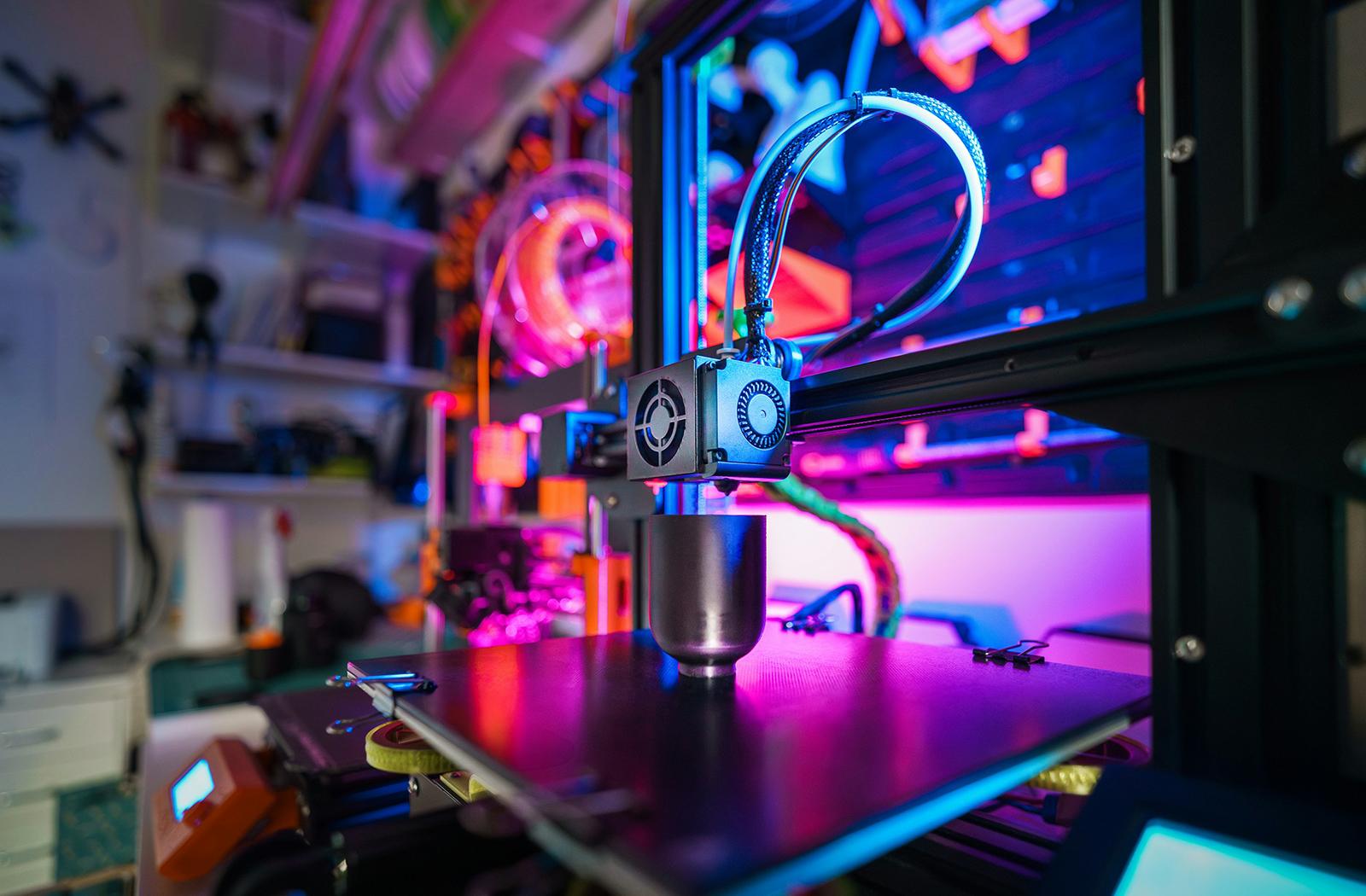

Digital transformation is reshaping the global industrial landscape. From artificial intelligence and smart robotics to 3D printing and the internet of things (IoT), new technologies are revolutionising how goods are produced, customised and delivered. For Commonwealth countries, particularly LDCs and SIDS, this shift offers a chance to fast-track industrial development, improve competitiveness and create sustainable jobs. Manufacturing 4.0 provides a pathway to harness these changes to boost productivity, expand value-added exports and strengthen economic resilience.

What is Manufacturing 4.0?

Manufacturing 4.0 refers to the integration of advanced digital technologies with industrial production systems, linking the physical and digital worlds through cyber-physical systems. These include AI, big data, cloud computing, robotics, blockchain and augmented reality. When adopted strategically, these technologies enable smarter products, more efficient processes and agile supply chains. This transformation is not just about automation, it is about empowering industries to innovate, adapt and thrive in the digital age.

Why it matters for development

Manufacturing remains a critical engine for development, contributing to 13 per cent of global employment and enabling countries to diversify exports, increase resilience and climb global value chains. Yet many LDCs and SIDS are falling behind in digital industrialisation. Investing in Manufacturing 4.0 can help close this gap by unlocking new sources of competitiveness, creating jobs for growing youth populations and meeting rising global standards around sustainability and traceability. As global trade and production systems evolve, countries with the right policies and capabilities will be best placed to seize new market opportunities.

Benefits for countries, firms and communities

- For countries: Manufacturing 4.0 drives productivity, boosts export readiness and strengthens industrial resilience.

- For firms: It opens new revenue streams, improves efficiency, reduces downtime and enhances responsiveness to market shifts.

- For workers and households: It creates demand for higher-skilled jobs, improves working conditions and delivers more affordable and sustainable products.

Challenges and risks

Despite the promise, many countries face barriers to adopting these technologies, particularly among small and medium enterprises (SMEs). Challenges include skills gaps, limited digital infrastructure, access to finance and weak innovation ecosystems. Without inclusive policy responses, there is also a risk of widening social, economic and gender inequalities. Governments must act decisively to ensure digital industrialisation benefits all.

What governments can do

Policymakers have a critical role in shaping enabling environments that support inclusive uptake of Manufacturing 4.0. This includes:

- strengthening technical and vocational education and training (TVET) systems

- enhancing digital infrastructure and innovation ecosystems

- providing targeted support to SMEs through financing, digital advisory services, and incentives

- embedding gender-responsive and socially inclusive policies in digital industrial strategies

- aligning foreign direct investment (FDI) and trade policies to attract digital manufacturing opportunities.

How the Commonwealth is helping

The Commonwealth Connectivity Agenda is supporting member countries to advance digital industrialisation through research, technical assistance and peer-to-peer learning. Manufacturing 4.0: A Policymaker’s Guide has been developed to help governments – especially those of LDCs and SIDS – navigate the opportunities and challenges of the Fourth Industrial Revolution and craft tailored policy solutions that deliver impact.